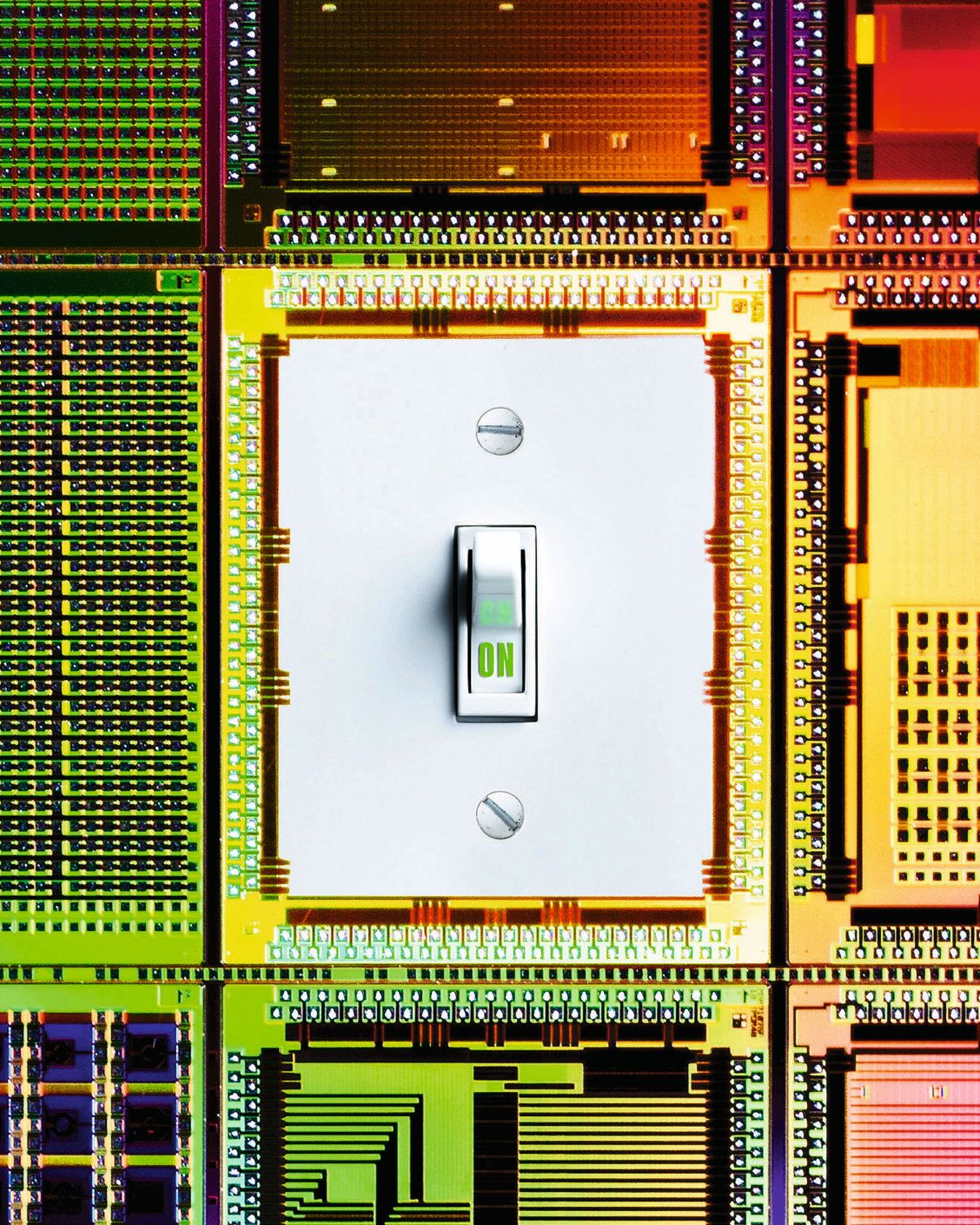

Smarter Electric Vehicle Inverters: AI Minimizes Power Loss

A Control Center with AI

Intelligent soft switching with AI support promises to reduce switching losses in power transistors by up to 95 percent. Porsche Engineering is already testing the new approach in simulations.

Range is one of the most important criteria when it comes to purchasing an electric vehicle. It is therefore crucial that all available options to increase powertrain efficiency are used. The inverter offers a lot of potential here, because noticeable losses occur in the inverter’s power transistors during switching. These losses can, however, be significantly reduced by intelligent actuation of the transistors.

Gently Does It: Losses in the inverters of electric vehicles can be significantly reduced by intelligent actuation of the transistors.

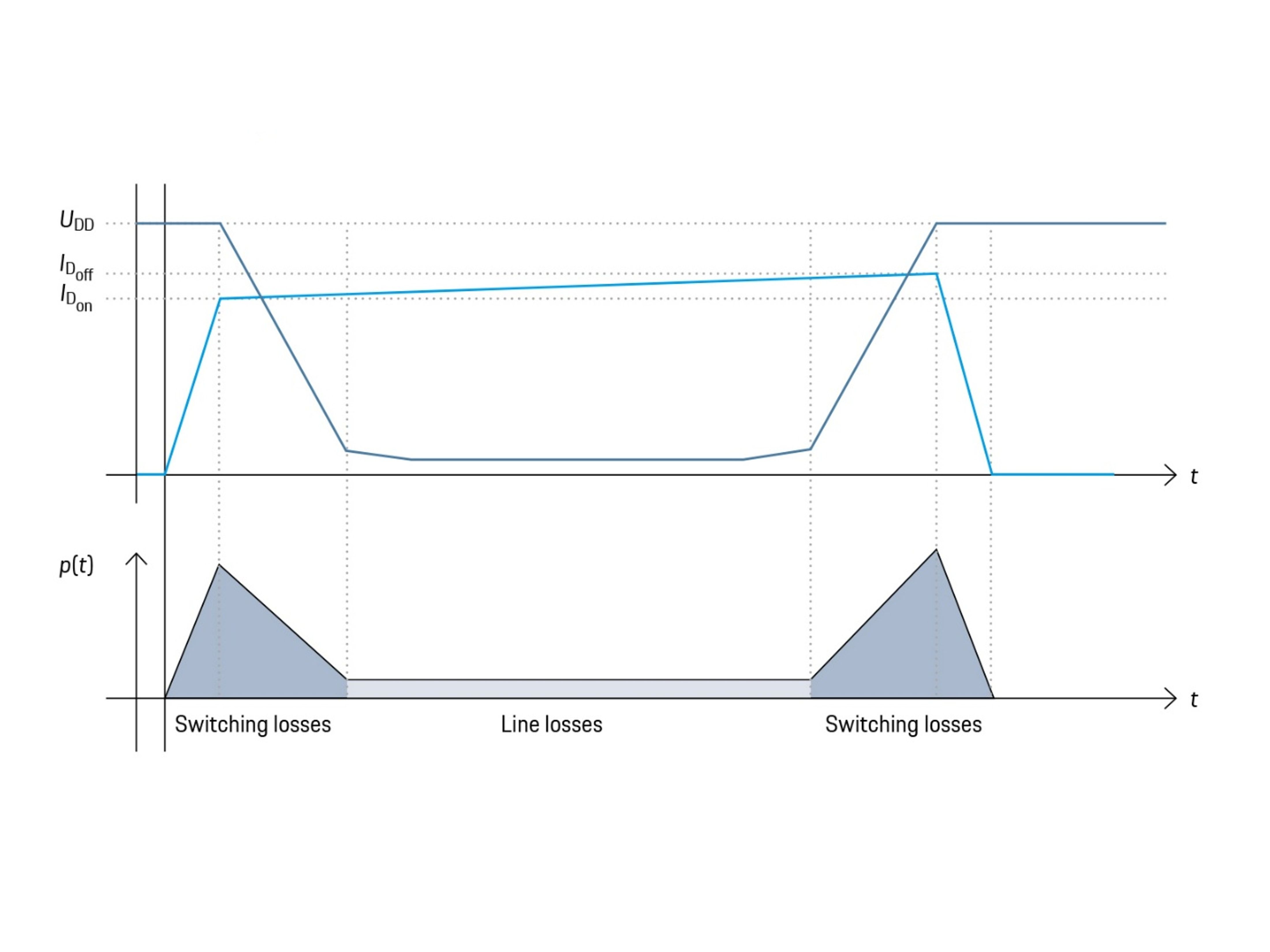

In principle, two primary types of losses occur in the inverter of an electric vehicle: Line losses and switching losses. Line losses are a physical property of the transistors, and one that cannot be influenced by the inverter’s circuit design. For physical reasons, a power transistor does not behave like an ideal switch that would conduct current without loss. Instead, even when it is switched on, the transistor still exhibits a low residual resistance, which leads to losses and heat generation.

Switching losses occur during the transition between the “On” and “Off” states. A voltage is present at the power transistor for a short time, even while a noticeable current is already flowing through it. The product of this current and the applied voltage is the undesired power loss. While switching on and off this power loss forms characteristic peaks that lead to energy losses—which ultimately reduces the potentially achievable range. “The more often the transistors are switched over, the greater the problem,” explains Volker Reber, Senior Manager Function & Software Development at Porsche Engineering. “Then again, high switching frequencies are welcome in the inverter, because this can improve the quality of the alternating current that is generated, among other things.”

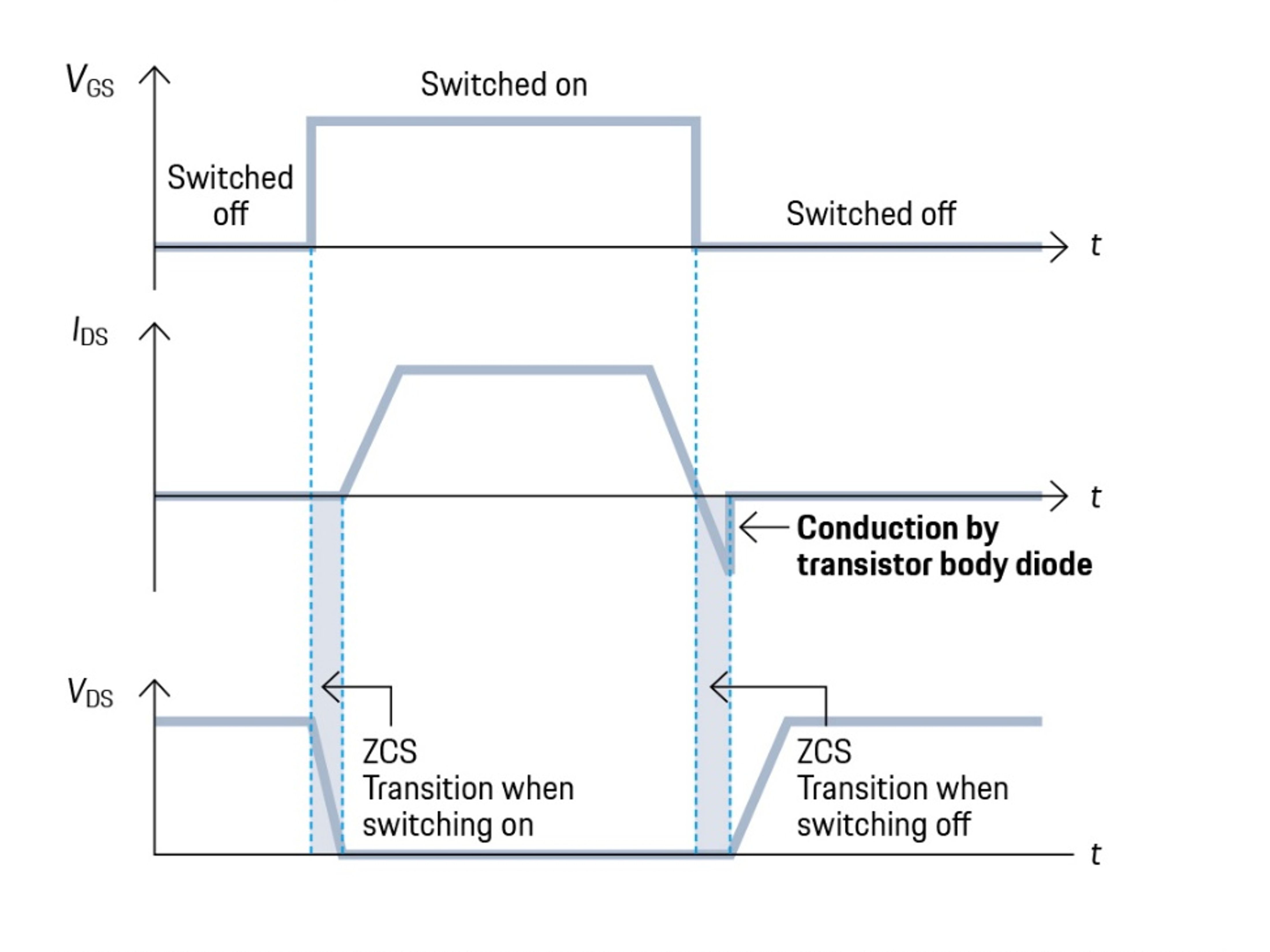

The way out of this dilemma is called “Soft switching”. While the power transistors in the inverter are switched on and off directly during “hard switching”, the changeover points are varied in real time so intelligently that the product of voltage and current at the transistor—and thus the power loss during switching—is minimized. There are essentially two ways of doing this: Zero Current Switching (ZCS) and Zero Voltage Switching (ZVS). With ZCS, the transistor is switched while almost no current is flowing through it. With ZVS, switching takes place when the voltage at the transistor is close to zero.

Smart Transistor Switching: How Soft Switching Increases a Vehicle's Range

Hard switching leads to typical peaks in power loss at the power transistors. The cause: During a transition period, a voltage UDD is still present at the transistor while current IDD is already flowing. The product of both results in the power loss.

With soft switching with Zero Current Switching (ZCS), switching occurs when there is hardly any current flowing through the transistor—which significantly reduces the power loss.

Soft switching with Zero Voltage Switching (ZVS) has the same effect. Here, switching occurs when the voltage at the transistor is close to zero—which also minimizes the power loss.

By using AI, Porsche Engineering optimizes the switchover times depending on the current operating conditions.

Reduced Losses Thanks to ZVS

Porsche Engineering uses ZVS to improve inverter efficiency. ZVS leads to lower losses in silicon-carbide and gallium-nitride power transistors, as are used in electric vehicles. In addition, it exhibits better efficiency at higher frequencies than ZCS, while disruptive electromagnetic interference is lower. Above all, ZVS is the better choice for inductive loads such as electric motors.

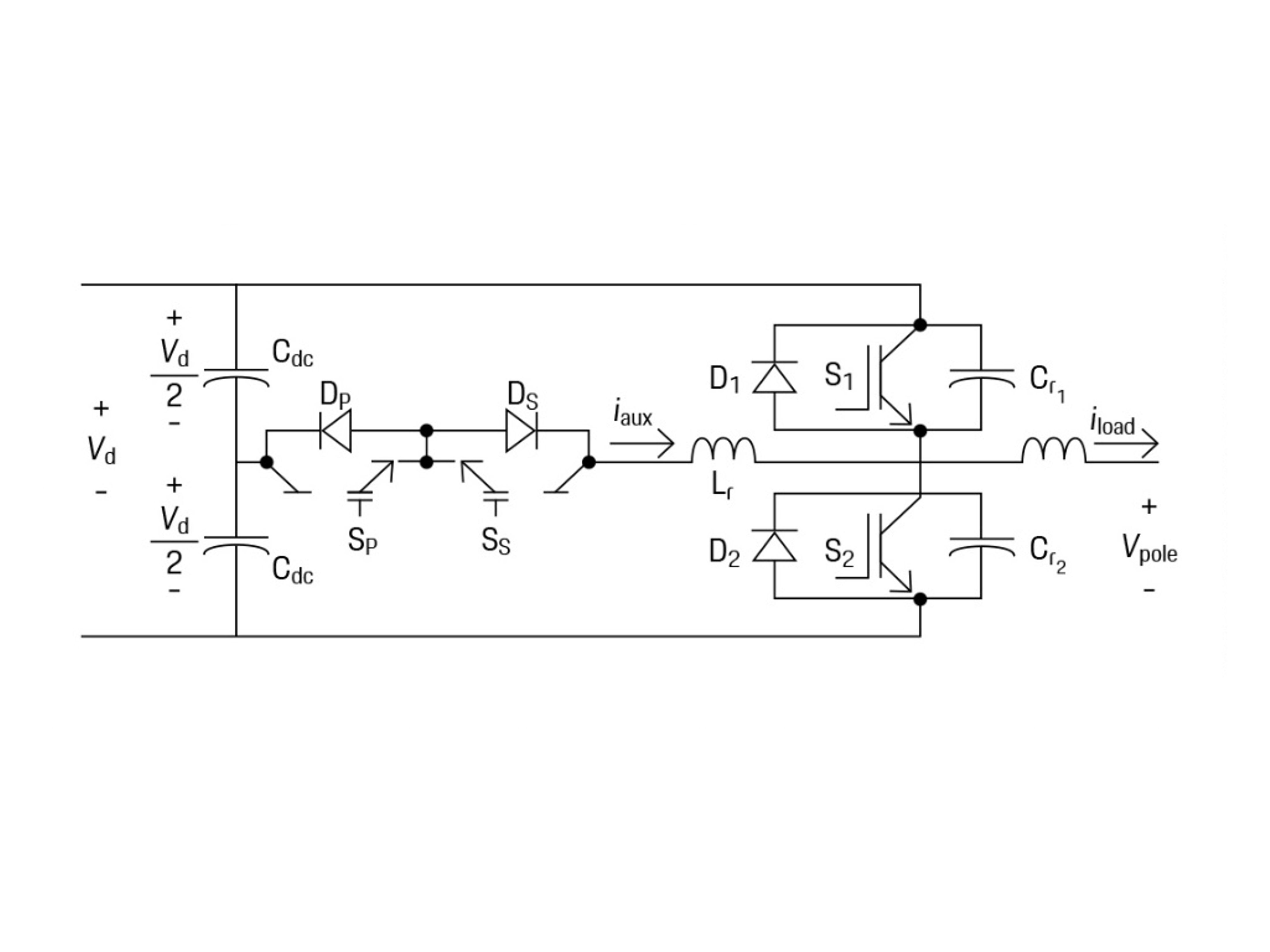

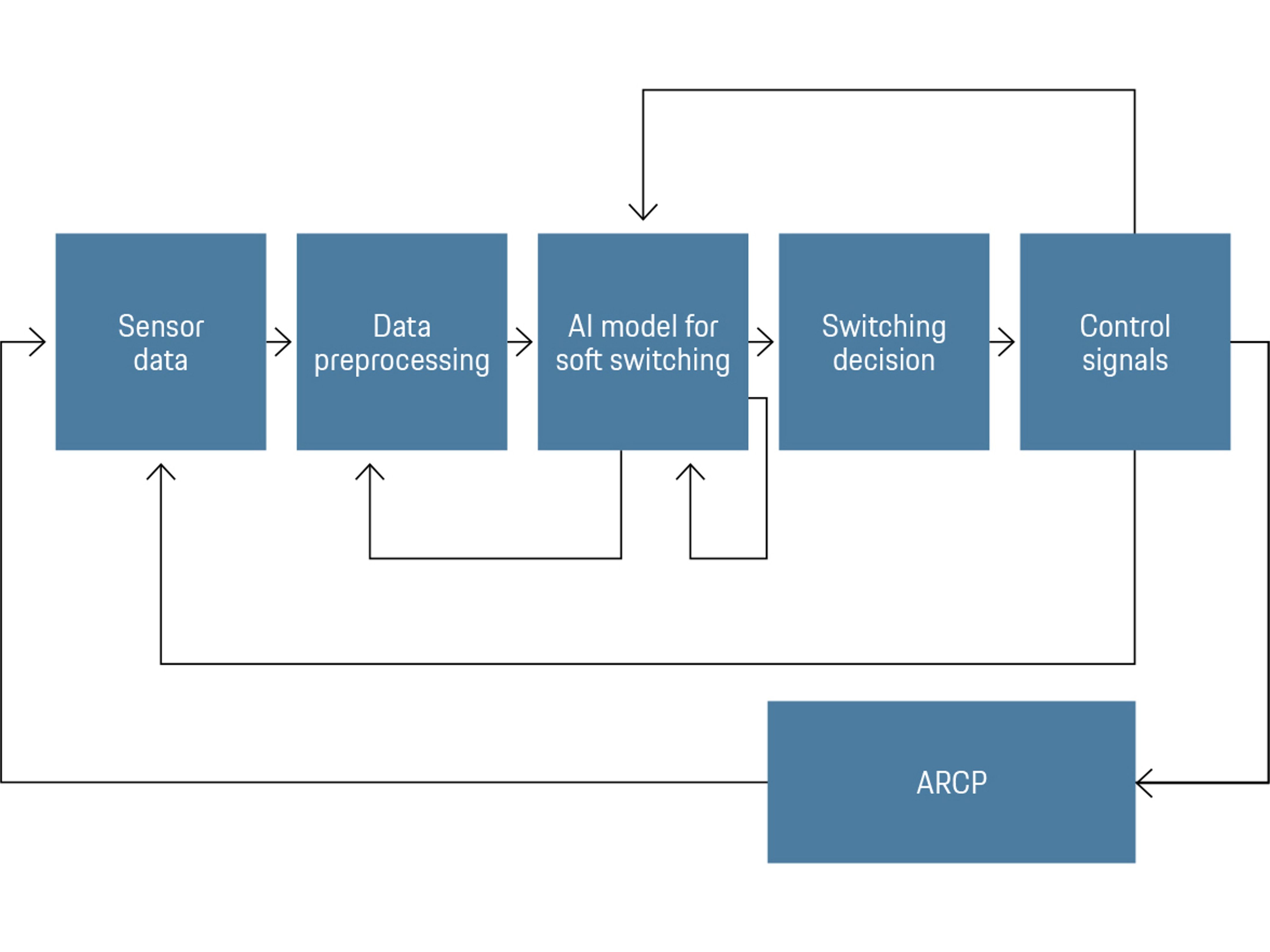

“Around the power transistors, we place an additional electronic circuit consisting of transistors, coils, and capacitors,” reports Souhaib Touati, Specialist Project Engineer Function & Software Development at Porsche Engineering. “This inverter topology has long been referred to as the auxiliary resonant commutated pole, or ARCP.” What’s new about Reber and Touati’s approach is the use of artificial intelligence to control the ARCP: A pre-trained AI algorithm processes several dozen live measurements from the electric vehicle in real time, such as load, torque, and temperature, from which it calculates the optimum switching times of the power transistors in fractions of a second.

The operating principle of an auxiliary resonant commutated pole (ARCP) is based on the use of resonance circuits to minimize switching losses in power electronics systems. The ARCP uses a resonant circuit that allows an interaction between inductances and capacitances. This resonance helps to control the voltage or current during the switching process. The switches (e.g. transistors) are controlled in a way that ensures that they are only switched on or off at zero voltage. This significantly reduces switching losses, as the switches do not switch under load. The switches are controlled using variable timing control, which takes into account the live load current in order to determine optimum switching times.

Switching Optimization with AI

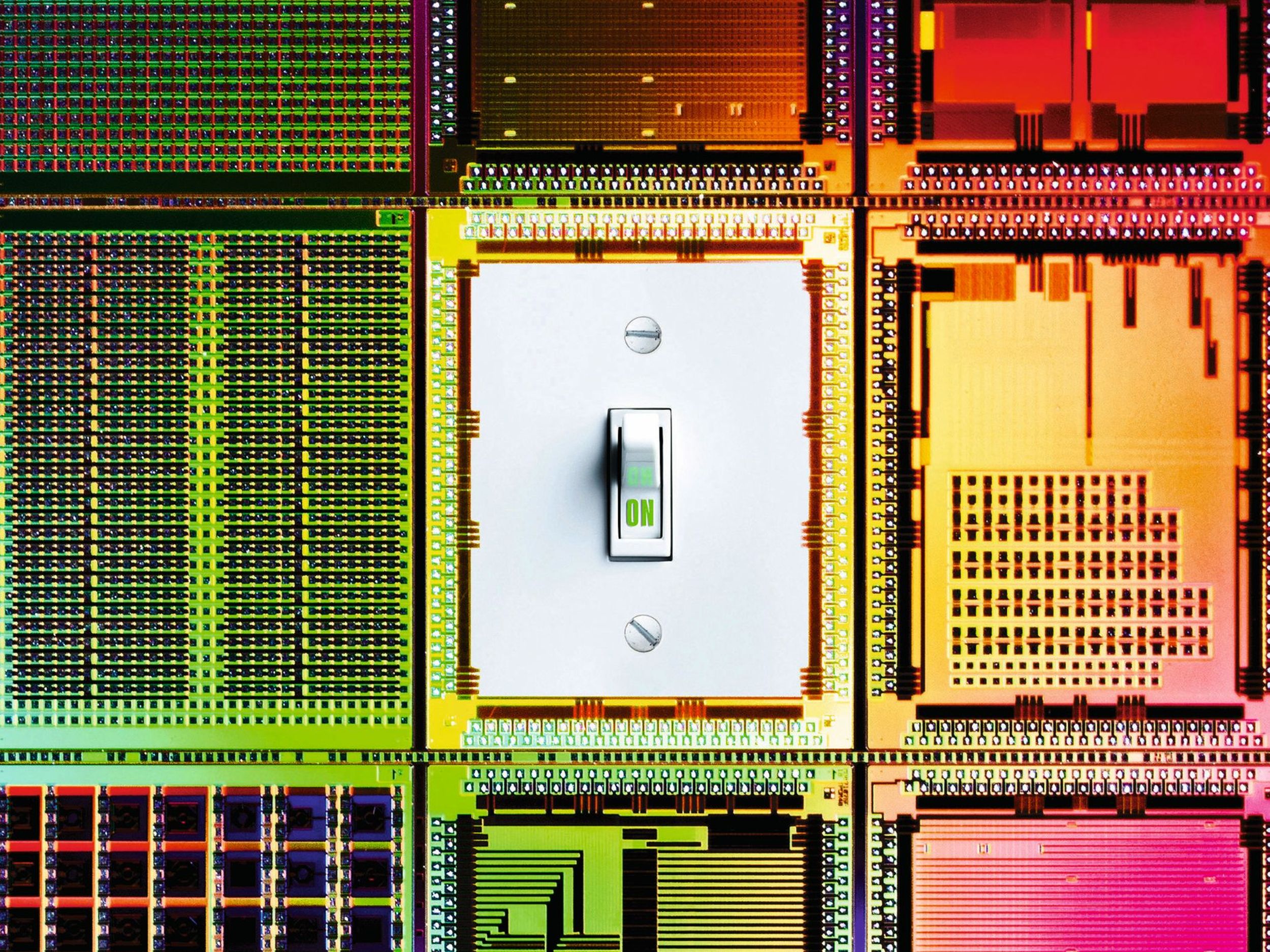

“An electric vehicle operates under constantly changing loads, which is why soft switching has not yet been applied in any other way due to the wide variety of rapidly changing operating conditions,” says Reber. “We were able to change that by using artificial intelligence to optimize transistor switching: Our algorithm predicts the optimum moments for controlling the ARCP, even under changing conditions. This allows us to achieve full soft switching with minimal losses and, as a result, higher ranges.”

“We achieve full soft switching with minimal losses and, as a result, higher ranges.”

Volker Reber

Senior Manager Function & Software Development at Porsche Engineering

Reber and Touati are currently investigating recursive neural networks and reinforcement learning as AI methods for intelligent soft switching. “Each has its own respective advantages: Recursive neural networks are characterized by high predictive accuracy and high performance,” says Touati. “Reinforcement learning increases the speed of calculations and is therefore particularly well suited for very demanding real-time requirements.”

The efficiency increase offered by the new approach is significant: Sodt switching losses in the power transistors by 70 to 95 percent. The range of an electric vehicle can thereby be increased, depending on how the vehicle is being used, by a high single-digit percentage. Soft switching also reduces heat generation in the pulse inverter due to the lower switching losses, resulting in lower cooling requirements and more compact components. Various filter components found in existing circuits can also be omitted, which further optimizes the printed circuit board (PCB) layouts. Overall, the volume of the pulse inverter decreases by 20 to 50 percent. What’s more: The hard switching used up to now places a heavy load on the power transistors in the inverter, thereby reducing their service life. This problem is also alleviated by AI-based soft switching.

Smart Switching: An electric vehicle operates under constantly changing loads. This is why the AI model continuously determines the optimum switching time based on current sensor data.

The new AI control algorithm for inverters is already at an advanced stage of development. As soon as it has been fully developed, Porsche Engineering will offer its customers AI-based soft switching as a complete software solution. “We will thereby offer OEMs and Tier-1 suppliers a big advantage: AI-based soft switching is implemented purely via software libraries and can therefore be integrated into existing control units in the same way as a plug-in,” says Touati. “The cost of modifying the hardware should be relatively low based on existing designs. AI-based soft switching could therefore be best implemented as part of a model update or new development.”

“AI-based soft switching is implemented purely via software libraries and can therefore be integrated into existing control units in the same way as a plug-in.”

Souhaib Touati

Specialist Project Engineer Function & Software Development at Porsche Engineering

Info

Text first published in the Porsche Engineering Magazine, issue 1/2025.

Text: Christian Buck

Copyright: All images, videos, and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written consent of Porsche Engineering. Please contact us for further information.

Contact

You have questions or want to learn more? Get in touch with us: info@porsche-engineering.de