)

FaSiP: Precision Testing for Driving Comfort

Vibrations Under Scrutiny

Porsche’s new road simulation test bench makes it possible to accurately reproduce real road conditions. This means that vehicle characteristics can be optimized and validated early in the development process—for Porsche sports cars and in other vehicle projects.

The humming is barely audible; it feels like a slight pressure on the ears. To find out where it’s coming from, the test engineer picks up his tablet. Using a slider, he minimizes the vertical excitation of the vehicle. The humming seems to be more prominent. To further home in on the source, the engineer taps the tablet again. He switches off the excitation of the front axle so that only the rear axle is excited in the longitudinal vehicle direction.

This is possible because the test is not taking place on the road, but rather on the new road simulation test bench (FaSiP) at the Porsche Development Center in Weissach. The simulator makes it possible to realistically reproduce road characteristics with a view to optimizing driving comfort. It also enables the individual control of axles—for example, to find the source of the humming. Shutting down the front axle quickly clarifies the matter: The noise is still present because the rear lid is being stimulated to vibrate by the rear axle. “In this case, a specially tuned absorber can be attached to the rear lid, which dampens these vibrations,” explains Dr. Sebastian Ihrle, Senior Manager Verification NVH in the Complete Vehicle Validation Characteristics and Simulation department at Porsche AG.

The acoustic and vibration characteristics play a decisive role in driving comfort. Regardless of the speed and the surface being driven on, no unpleasant noises, vibrations, or harshness, called NVH for short, may occur. This is a challenge for a manufacturer like Porsche with a wide range of products, as each model should have a characteristic vibration behavior that the driver experiences as positive—experts refer to this as the dynamic fingerprint. “With a sporty vehicle, customers expect relevant and significant feedback from the road surface and the driving situation, and with a more comfort-focused vehicle, they expect greater decoupling,” explains Rainer Gebhardt, Senior Expert Driving Comfort at Porsche AG. In a comfortable sedan, for example, a slight chattering would be much more unpleasant because it is not masked by the road excitation.

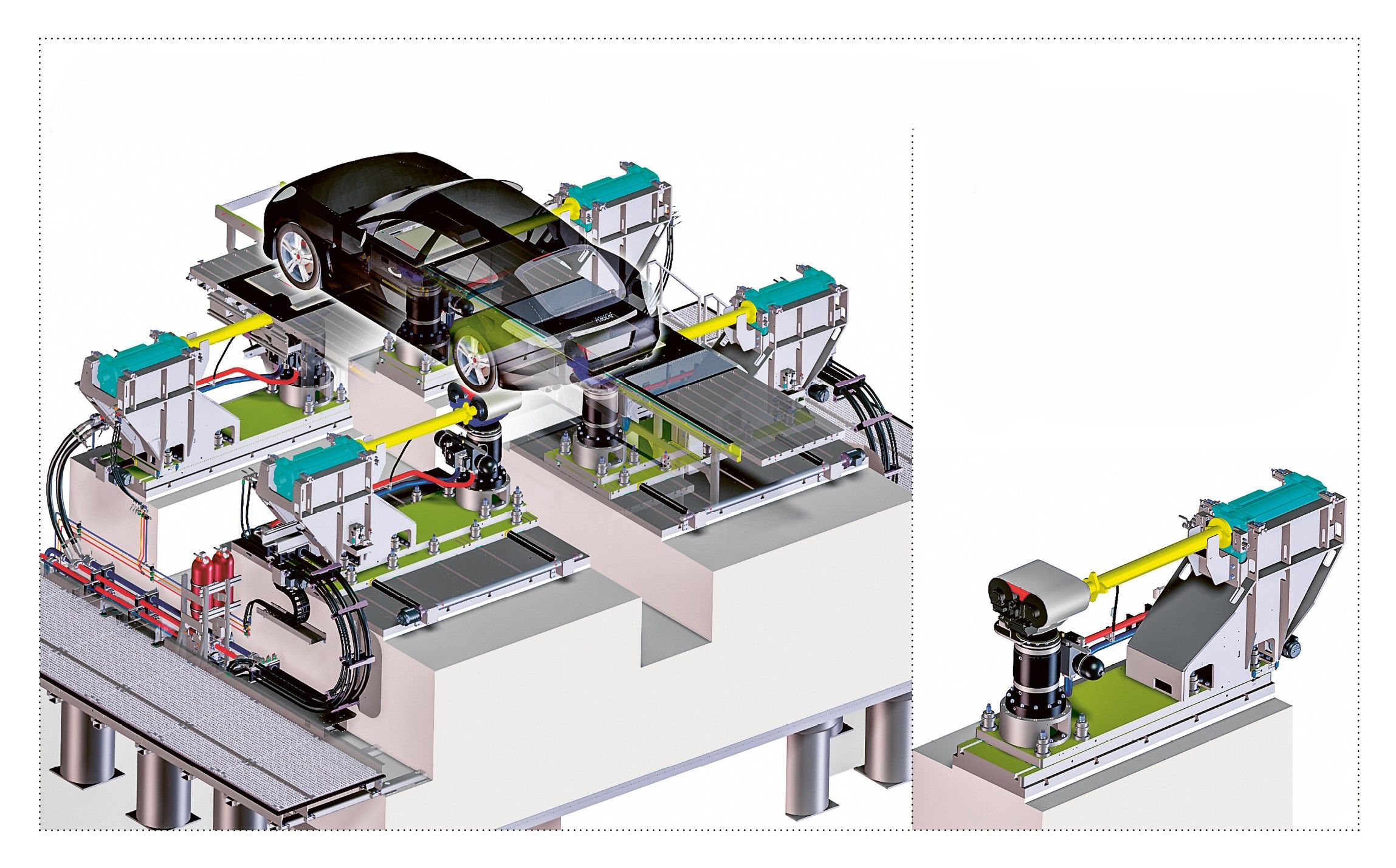

Optimizing Driving Comfort: The new road simulation test bench in Weissach can be used to test prototypes at early stages of development, like this predecessor to the current Porsche Panamera.

Testing at an Early Stage

In order to optimize the NVH properties of a vehicle, many real test drives are required in addition to virtual tests. However, in the past, these could only begin once a complete vehicle with driving clearance was available. At this relatively late stage in the development process, however, fundamental design changes are usually very costly to implement. Both of these limitations are eliminated by the test bench. Here, prototypes can be tested for their vibration characteristics in the early stages of the development process, so that even extensive adjustments can still be made without difficulty. Even individual components or modules can be tested (hardware-in-the-loop tests, HiL). For example, engineers can send a single axle, clamped into a special frame, on a test drive. “As a result, we get ‘on the road’ much earlier in the development process”, says NVH expert Ihrle.

“Using the FaSiP, we get ‘on the road’ much earlier in the development process.”

Dr. Sebastian Ihrle

Senior Manager Verification NVH in the Complete Vehicle Validation Characteristics and Simulation department at Porsche AG

Complex technology is used to accurately reproduce real drives: The vehicle is flexibly mounted on the FaSiP—in straight-line driving—with all wheels standing on four independent belt units. Each tire rolls on a 0.4-millimeter-thick steel belt driven by a highly dynamic electric motor. By changing the belt speed, longitudinal forces are applied to the tire, causing the vehicle to vibrate in the longitudinal direction (forward and back). In addition to this, servo-hydraulic cylinders below the belt units generate vertical impulses (up and down). The interplay between these factors can precisely reproduce forces as they occur in real driving conditions, whether due to a poor road, a change in road surface, or manhole covers.

250

km/h

It is crucial for the wheels to be turning during the test-in contrast to test benches where the forces are supplied by hydraulic pistons while stationary. There are, after all, numerous physical differences between a stationary and a rolling vehicle. “The tire stiffness is different when the wheel is stationary, and the resonances also shift,” explains expert Gebhardt. The FaSiP realistically reproduces driving in both dimensions.

What’s more, it’s also easier for engineers to focus on individual aspects. While driving on the road always provides an overall acoustic profile, the FaSiP allows a vibration range to be controlled precisely and reproducibly, just like in a recording studio. The test bench functions something like a magnifying glass. “For example, we can specifically test the imbalance behavior of the wheel and tires,” explains Ihrle. If a factor remains constant, the best technical solution can be found more quickly through experimentation. Without a precise tool like the FaSiP, the development and validation of driving comfort would be much more complex in the future. This is because the interaction of the technology in cars is becoming increasingly complex, for example due to intelligent mechatronic systems that ensure an optimal balance between performance and driving comfort—such as variable current supply to the dampers depending on the driving situation. Checking all possible combinations and their effects on road test drives would involve a great deal of effort. “Tools such as the FaSiP are particularly useful in managing the conflict between the need for systemic validation in the face of increasing complexity and the simultaneous shortening of development times,” says Ihrle.

Investigating Causes on the Road Simulation Test Bench

A comparison between measurements and the test bench show how precisely the FaSiP can reproduce the accelerations on the wheel carrier (top). In both the longitudinal (x) and vertical (z) directions, the curve measured on the road and the one measured on the test bench are almost exactly the same. Driving on the FaSiP is also very close to reality (center) when it comes to measuring the noise level in the vehicle interior. By selectively switching excitations on and off in a longitudinal or vertical direction, the developers are able to identify the cause of the humming: It is, contrary to expectations, caused by the longitudinal excitation. The vertical excitation does not play a role in this phenomenon.

Identifying Noise Problems

The test bench is also ideally suited for what is known as “firefighting” in the technical jargon: An industrial customer books the FaSiP because a problem with the acoustics has unexpectedly occurred on a model that is ready for series production. When sitting in the vehicle, the development engineer can use the control tablet to modify or remove specific excitation components and frequency ranges in order to pinpoint the disturbing problem with the acoustics. The subjective perception is then transformed into objective parameters based on the recorded data, which helps solve the problem in a systematic and efficient manner. The location at which the disturbance originates is irrelevant, as the test route of the industrial customer can easily be “Recreated”. On the FaSiP, we can reproduce any vibration phenomenon that has occurred on the vehicle anywhere in the world, analyze the causes, and optimize it,” says Gebhardt.

“We can reproduce any vibration phenomenon that has occurred on the vehicle anywhere in the world, analyze the causes, and optimize it.”

Rainer Gebhardt

Driving Comfort Senior Expert at Porsche

The new road simulation test bench has been in operation since mid-2024 and is used by Porsche AG for development. It can also be booked by industrial customers, such as other vehicle manufacturers, through Porsche Engineering. Two factors make the test bench unique worldwide: One is that speeds and road excitations can be simulated up to 250 km/h, which is essential for sports car development. The other is that vertical movements of the belt units of up to plus/ minus 40 millimeters are possible. The excitation can be applied across a broad frequency spectrum ranging from 0 to 50 hertz. “Ranges as large as this are important in order to observe the movements of the vehicle body,” explains expert Ihrle. The convenient operation of the system in real time using a tablet is also unique. The new test bench is an important link in vehicle development, which is becoming increasingly virtual, especially in its early stage. When there is a distinct virtual early phase, it is expedient to check the acoustic and vibration behavior in detail under real conditions and make any corrections necessary before the results of test drives become available in a later phase. This is now possible on the new road simulation test bench. With the help of this early „hybrid testing“, it will be possible to develop driving comfort characteristics even more efficiently in the future, which ultimately saves time and money.

≤

50

hertz

Above all, the test bench demonstrates its strengths where vehicle parts behave in a complex manner due to their material properties and are therefore difficult to simulate on the basis of virtual methods. This includes elastomers, for example, which are plastics that return to their original state after being deformed. “With these materials, double the force does not mean double deformation,” explains Ihrle. To explore their behavior in the complete vehicle, testing is the key.

Combining Testing and Simulation

In view of this complexity, the development engineers have two options: Either they put a great deal of effort into refining the simulation model—or they test with physical hardware. In practice, a hybrid solution is increasingly emerging. “Physical checks are made on everything that is complex or highly nonlinear, the rest is simulated,” says Ihrle. In doing so, the findings from the real and digital worlds complement each other. Porsche uses data from the FaSiP, for example from axle tests, to make computer simulations even more precise.

±

40

mm

In addition, the FaSiP could be supplemented in the future with a completely new approach: AI-supported optimization of driving comfort. Porsche Engineering is currently developing neural networks that have learned through intensive training to objectively assess driving comfort. Together with the FaSiP, they enable more automated development, which in turn is associated with lower costs and input: After basic tuning based on a fully virtual application, the vehicle would repeatedly drive the same route on the test bench—without a test engineer on board—with specially installed acceleration sensors recording the vibrations that occur. Using this data, the AI could then evaluate comfort according to defined characteristics. The chassis parameters of individual systems are then changed—and the test is repeated. In the final step, the driving dynamics experts come into play and get to work on the fine-tuning that characterizes the brand.

Precise Reproduction of Road Surface Excitation

Four independent belt units form the heart of the road simulation test bench. Each of them consists of a 0.4-millimeter-thick steel belt (silver) driven by an electric motor (light blue) via a drive shaft (yellow) and on which the tires of the test vehicle roll. Changes in belt speed produce longitudinal vibrations while servo-hydraulic cylinders (black) generate vertical impulses.

Info

Text first published in the Porsche Engineering Magazine, issue 1/2025.

Text: Constantin Gillies

Copyright: All images, videos, and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written consent of Porsche Engineering. Please contact us for further information.

Contact

You have questions or want to learn more? Get in touch with us: info@porsche-engineering.de