October 2025

The future of electric mobility takes shape at Nardò Technical Center: the Battery Testing Site is renewed with cutting-edge technologies

Nardò Technical Center (NTC) enhances its turnkey battery testing service with the latest technologies, following the major refurbishment of its site, now transformed into a state-of-the-art centre for indoor battery testing. The renewed infrastructure, combined with NTC’s proven instrumentation and deep technical expertise, allows the facility to offer a comprehensive, fully integrated service that meets the evolving challenges of electric mobility and expands the range of testing capabilities.

Certified expertise driving innovation

The team at NTC combines deep technical knowledge with DGUV-certified expertise (Deutsche Gesetzliche Unfallversicherung - German Social Accident Insurance). Their capabilities span thermal propagation, fire-resistance, post-mortem analysis, short-circuit and abuse testing, ARC (Accelerating Rate Calorimetry), and CFD (Computational Fluid Dynamics) thermal simulations.

Beyond testing, the team is also highly skilled in instrumentation setup, data acquisition, and post-processing, with additional strengths in FTIR (Fourier Transform Infrared) gas analysis, dielectric-oil characterization, and hazardous materials logistics. Supported by dedicated personnel, including firefighters and logistics staff, the team ensures precision, safety, and innovation in every project.

Comprehensive battery testing with real-time insights

Designed for full-spectrum testing, the Battery Testing Site at Nardò Technical Center supports every level of battery integration—from individual cells and modules to full packs for BEV (Battery Electric Vehicle), PHEV (Plug-in Hybrid Electric Vehicle), and MHEV (Mild Hybrid Electric Vehicle), reactors, and complete vehicles. Its advanced technologies enable precise replication of test scenarios to analyze thermal events, evaluate containment systems, and verify protection devices.

Thanks to a comprehensive suite of advanced technical instruments, clients benefit from a fully digital experience with secure live streaming and comprehensive data acquisition through standard, infrared, and high-speed cameras. Post-test analysis, supported by a specialized chemist, transforms data into strategic insights that drive continuous improvement in battery safety and performance.

A high-tech infrastructure for continuous testing

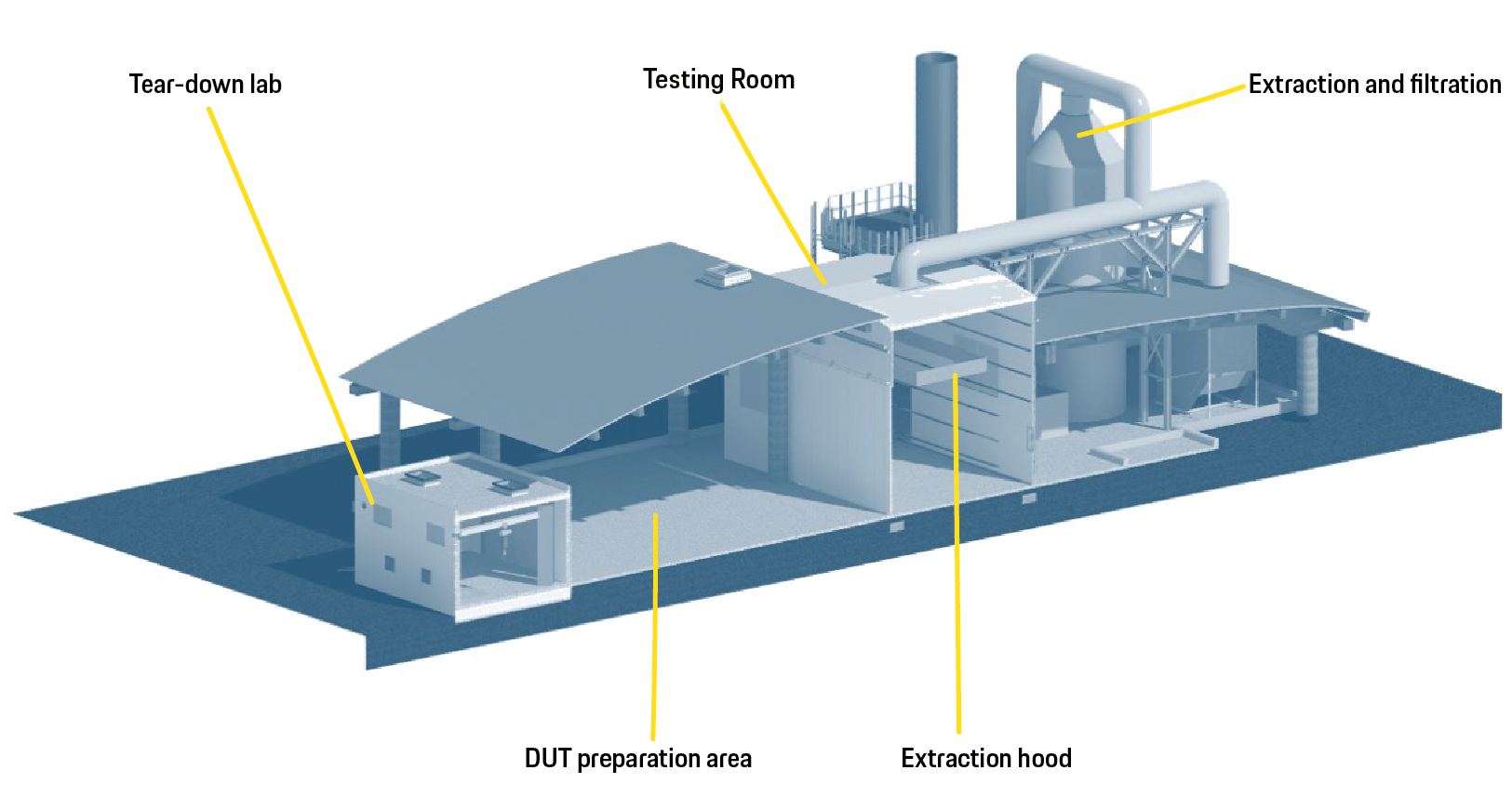

Engineered for round-the-clock operation under rigorous safety conditions, the Battery Testing Site integrates fire-resistant steel paneling, advanced ventilation systems, and a high-capacity extraction unit with an integrated hood for safe substance handling. Overpressure panels further enhance safety during extreme testing scenarios.

The facility includes:

a battery tear-down zone for disassembly and immediate analysis

a DUT (Device Under Test) preparation area

a controlled lab space for precision testing

an immersion tank capable of accommodating vehicles up to SUV category

Together, these elements enable complex testing under controlled conditions, ensuring both safety and optimal performance.

Where innovation meets expertise.

Beyond the renewed facility, what truly defines NTC’s turnkey service stands out for the synergy between advanced equipment and specialized expertise — powered by highly skilled team whose passion for innovation drives NTC’s commitment to safe, efficient, and electric technologies.

Discover more about the service